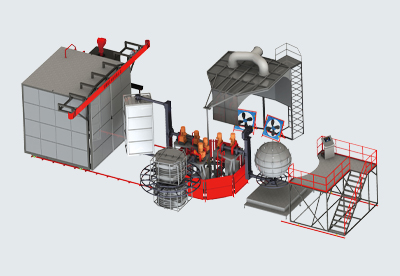

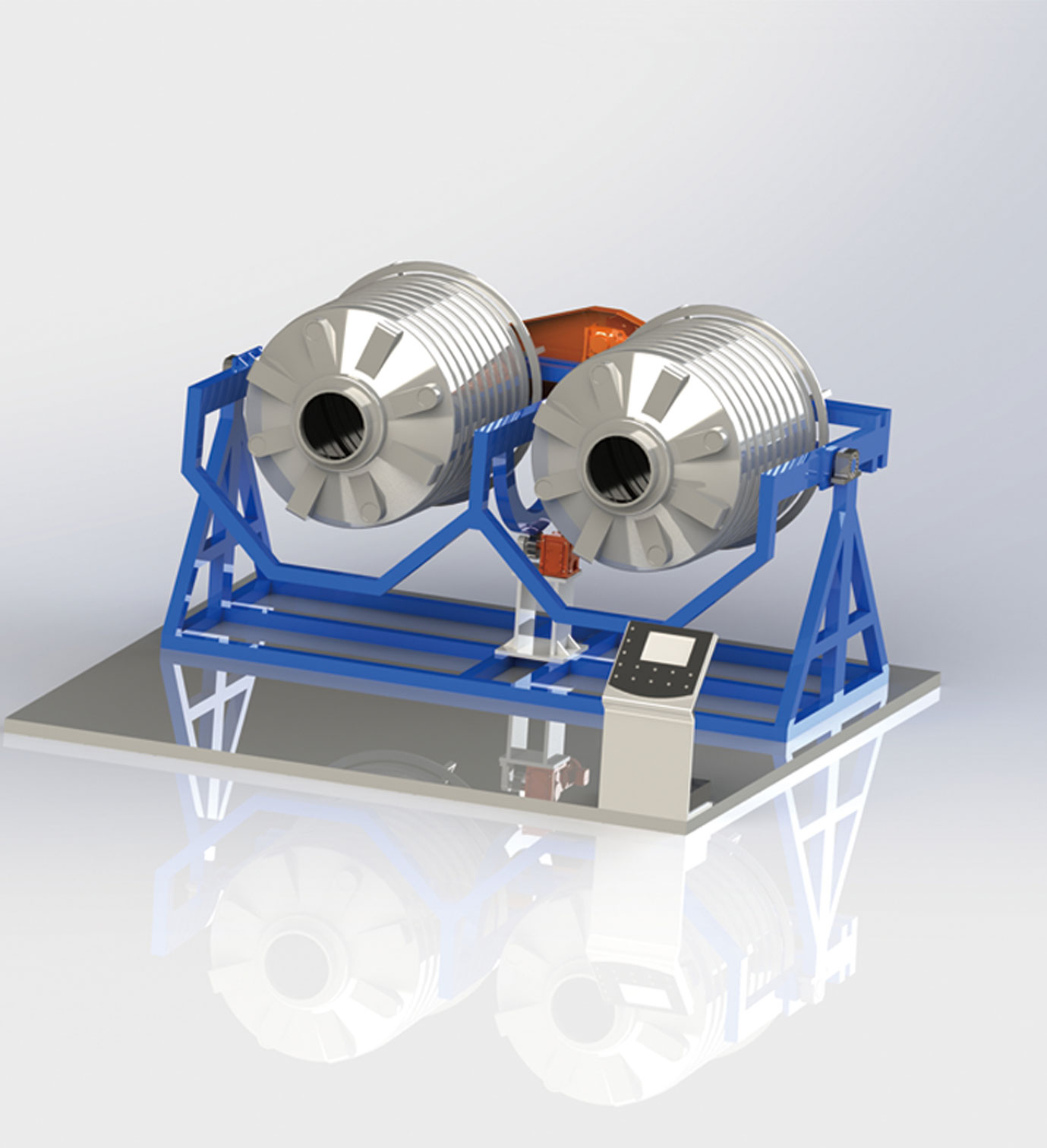

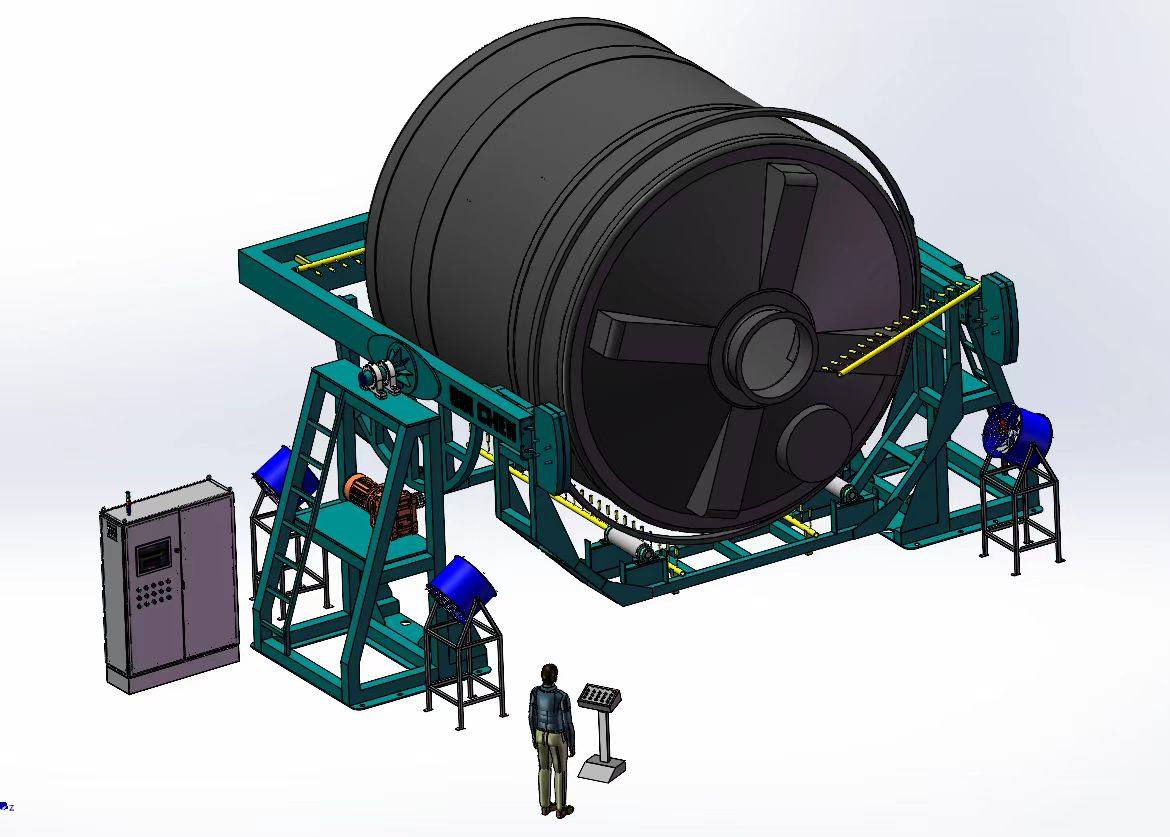

There are three types of open flame swing rotational molding machines: mini

type, pit type, and pit free type. Customers can customize single or double

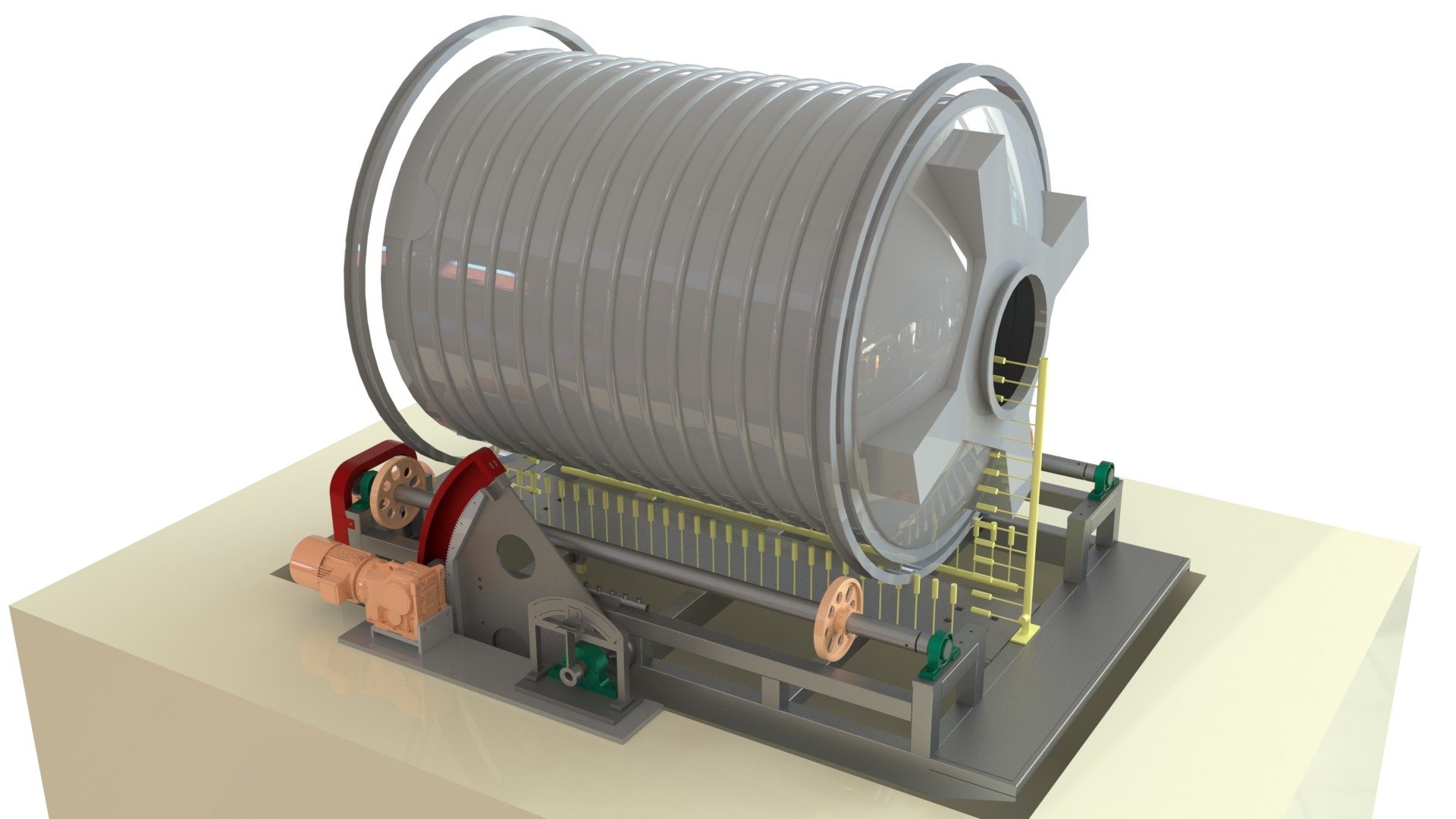

barrel processing types according to their needs. It abandons the traditional

swing machine that relies on link motor and hydraulic transmission to achieve

swing. The link transmission is unstable and easily damaged, and the hydraulic

cylinder is difficult to maintain; This machine adopts a motor-driven rack to

achieve swinging, which has the advantages of adjustable angle, smooth

transmission, and easy maintenance.

Equipment features: Low equipment cost, small footprint, easy operation and

maintenance, making it an ideal entry point for rotational molding.

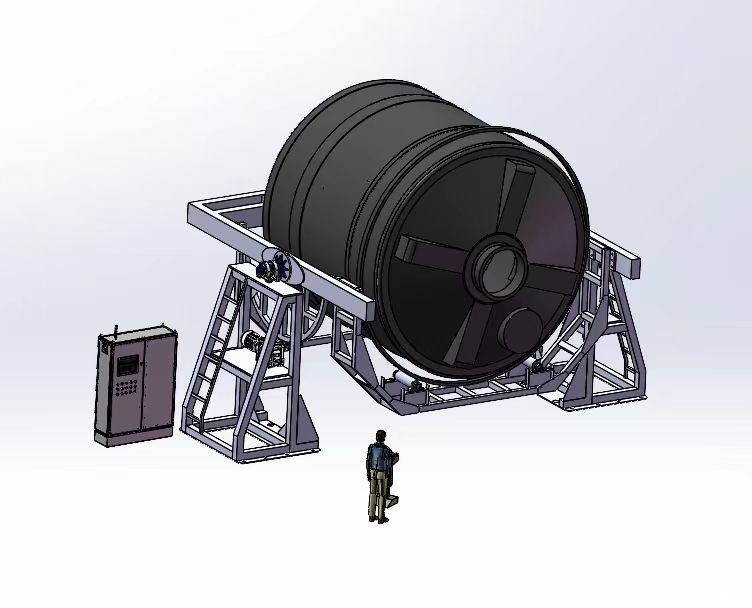

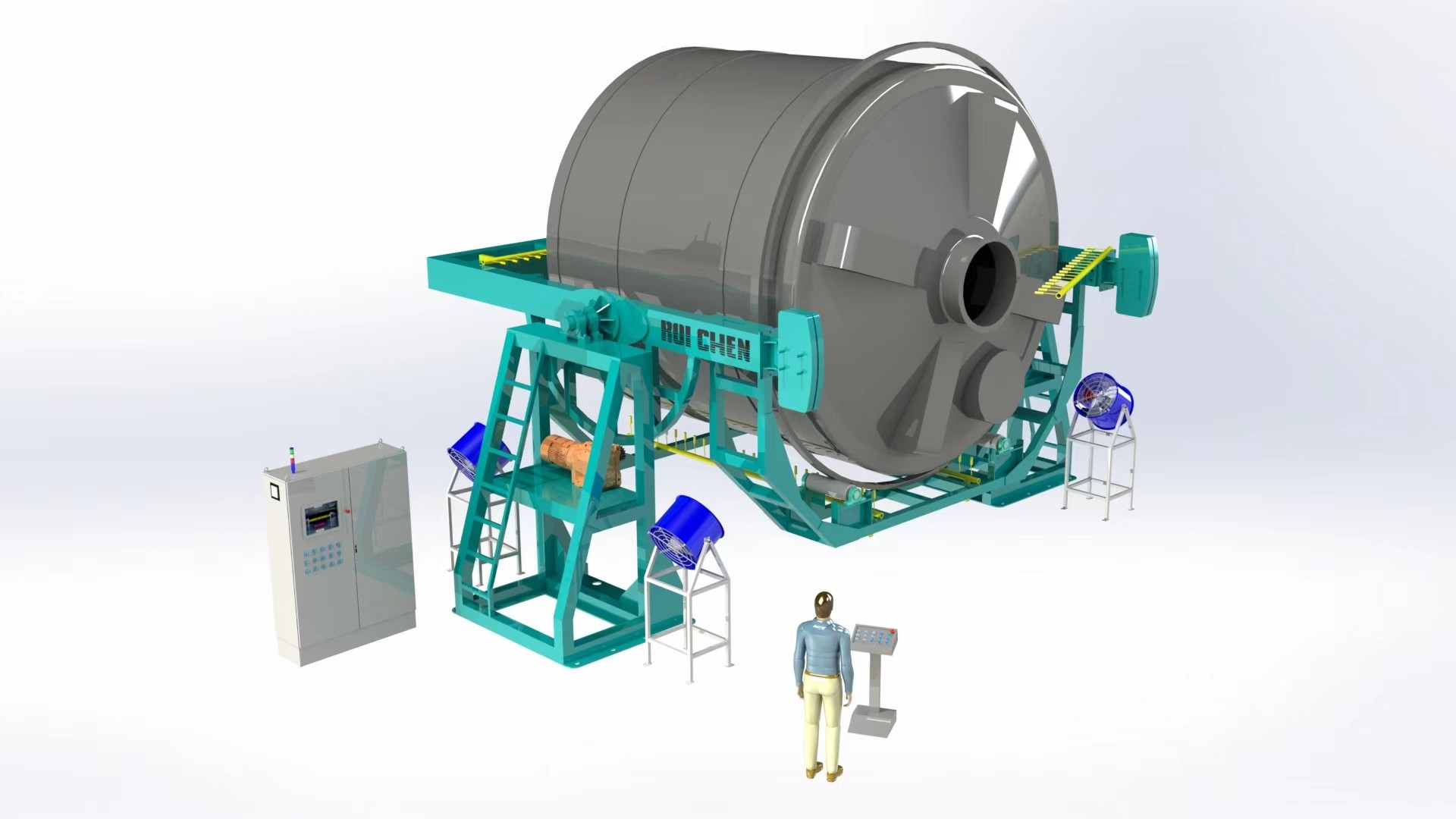

Suitable for making large and medium-sized hollow products, such as water

tanks, water towers, ton drums, etc. There are three types of open flame swing

rotational molding machines: mini type, pit type, and pit free type. Customers

can customize single or double barrel processing types according to their needs.

It abandons the traditional swing machine that relies on link motor and

hydraulic transmission to achieve swing. The link transmission is unstable and

easily damaged, and the hydraulic cylinder is difficult to maintain; This

machine adopts a motor-driven rack to achieve swinging, which has the advantages

of adjustable angle, smooth transmission, and easy maintenance.

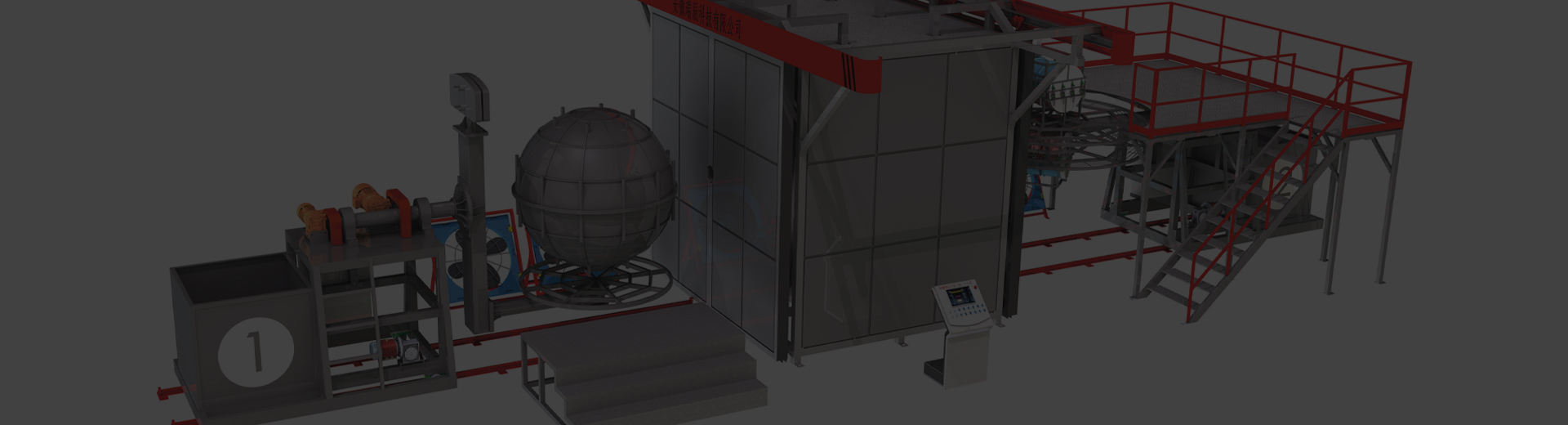

This type of equipment has low cost and is suitable for manufacturing large

and ultra large plastic hollow products (such as steel lined plastic, pipe lined

plastic, etc.).

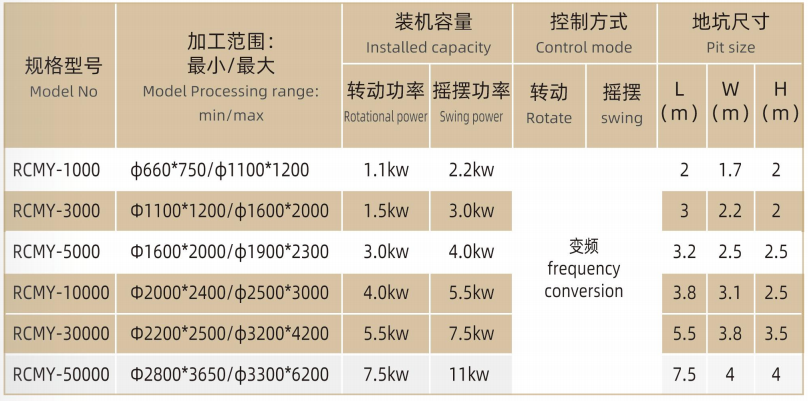

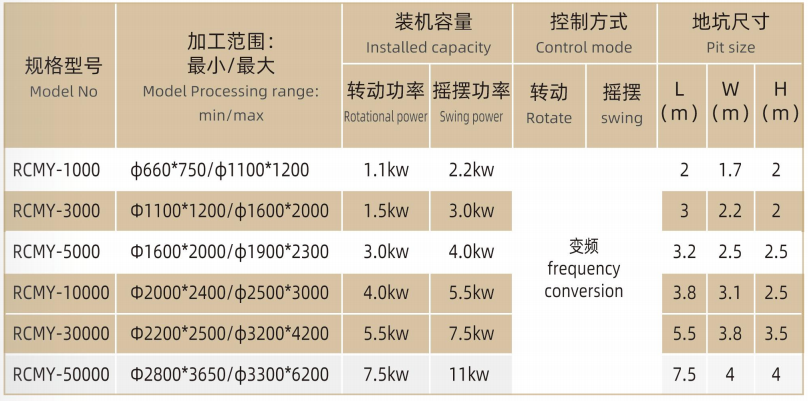

Model:RC-MY-1000、RC-MY-2000、RC-MY-3000、RC-MY-5000、RC-MY-10000

Easy to operate: The operation process is relatively simple and easy to get

started with.

Convenient transportation: The equipment is easy to transport and

install.

Wide applicability: Suitable for the production of multiple varieties and

small batches of plastic products, easy to change the color of the products.

Efficient utilization of raw materials: There is almost no waste or recycled

materials in the production process, which is conducive to saving raw

materials.

Phone:

+8613865558212

Phone:

+8613865558212

Phone:

+8618156567276

Phone:

+8618156567276

Phone:

+8618155517338

Phone:

+8618155517338

Add:

Building A22, Aux Intelligent Manufacturing Industrial Park, Ma'anshan, Anhui Province

Add:

Building A22, Aux Intelligent Manufacturing Industrial Park, Ma'anshan, Anhui Province