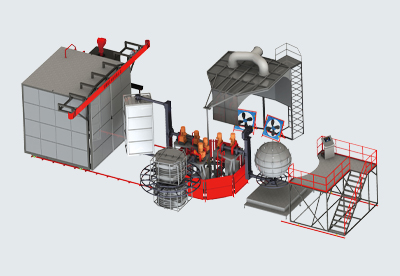

Rolling molding process refers to the use of rolling molding equipment to heat and melt the rolling molding raw materials, then cool and demold them, and finally produce independent rolling molded products. At present, rotational molding has been widely used in automobiles, road transportation, sports and entertainment, various boxes, shells, large pipes, as well as toys, models, handicrafts and other parts.

In Europe and America, the application of rotational molding in the field of lighting fixtures is relatively mainstream, and even a trend in high-end lighting fixtures. So, what are the advantages of rotational molding lampshades?

What are the advantages of rotational molding lampshades?

Firstly, the rolling plastic lampshade is generally made of PE material, which is waterproof, dustproof, easy to clean, UV resistant up to level 8, durable and non fading. Compared with glass materials, it has the advantages of collision and drop resistance. The PE lampshade is milky white in color, with a frosted texture and a sense of luxury, which can be matched with different decoration styles.

Secondly, the transparency of roll molded lampshades is generally around 78%, which can make the light source soft and uniform. It can create atmospheres such as personality, warmth, tranquility, or beauty according to needs, suitable for home atmosphere lighting, and can also be applied to bars KTV、 Outdoor decorative lighting such as stage parties can be considered a perfect fusion of practicality and artistry.

Furthermore, the rotational molding lampshade is not yet popular in China, and there is huge potential for future market development. With unlimited business opportunities now, Chuangxinliang's rotational molding lampshade and its rotational molding products are of superior quality, selling well for over 1 million, and have an excellent market reputation. It is your first choice for high-end rotational molding products. Welcome brand friends from all walks of life to consult!

Phone:

Phone: Add:

Add: