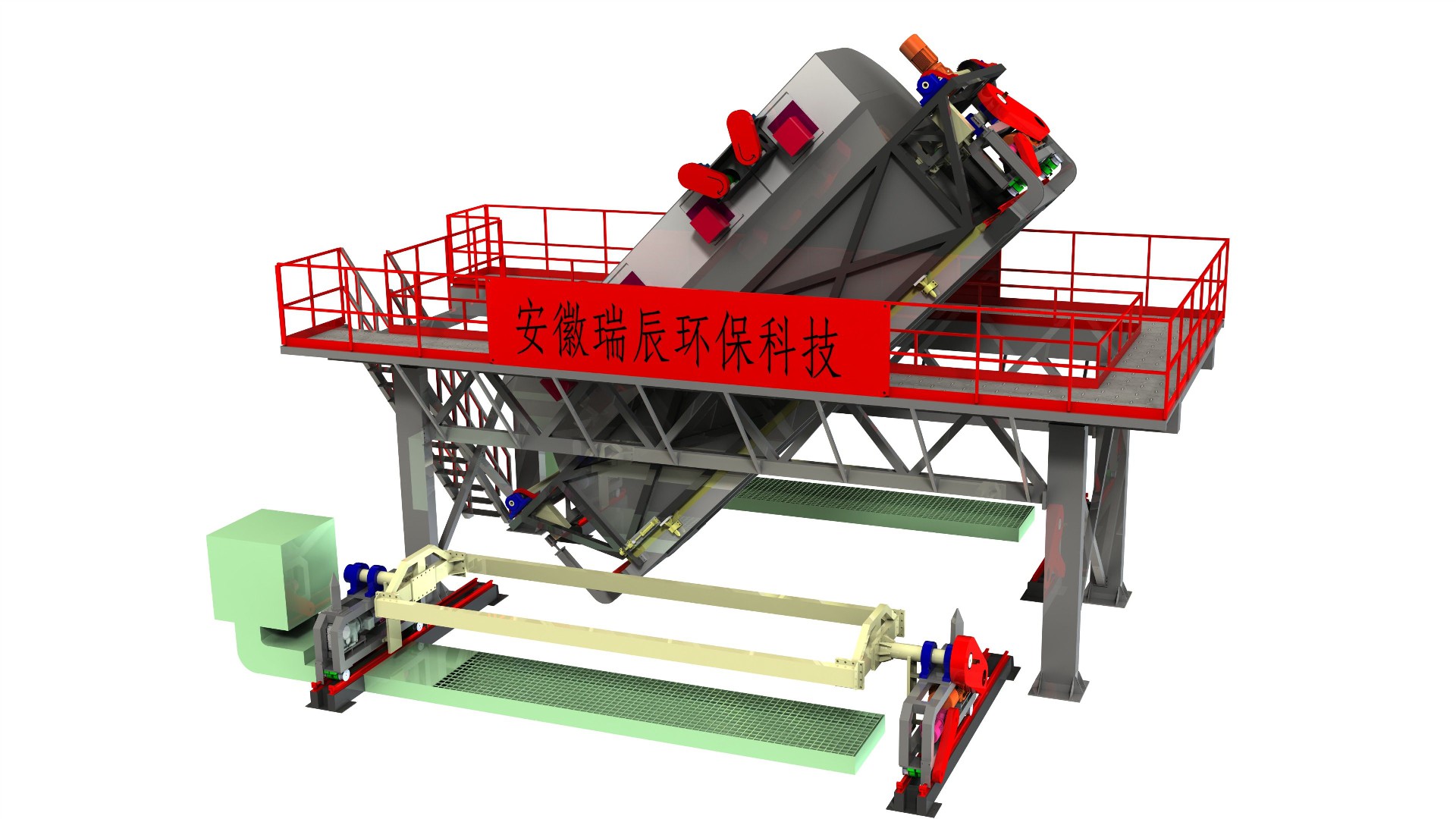

The quality of a rolling molding machine is not measured by the price of purchase or customization. It is not uncommon to spend a high price on a poor quality rolling molding machine. A high-quality and efficient rotational molding machine is not only a simple combination of mechanical and electrical components, but also involves rotational molding processing technology and software technology. The rotational molding process is related to rotational molding materials, molds, etc. Only after mastering various situations can the relevant heating rate, heating time, rotation speed settings, etc. be formulated.

The selection of materials and heat treatment methods for rotational molding equipment/rotational molding machines are also important. Directly related to the service life of the rotational molding equipment, some transmission components operate under high temperature, low speed, and heavy load conditions, and alternating cold and hot can cause deformation of some parts, leading to malfunctions. So, what standards are used to measure the quality of a rolling molding machine? Here are a few reference suggestions.

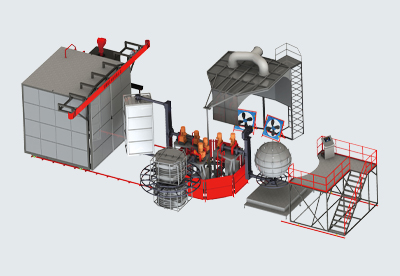

① Reasonable structure. The equipment is lightweight, the overall design is simple, the layout is reasonable, delicate and sensitive, the load is reasonable, and there is no redundancy or complexity.

② The temperature is uniform. During the molding production of the rolling molding machine, the hot air channel in the heating chamber is smooth, and the heat distribution is uniform. Except for the air outlet, there is no situation where some areas have high temperatures and some areas have low temperatures, especially no temperature blind spots.

③ Heating up quickly. The heating chamber can reach the rated temperature in a short period of time, indicating high thermal efficiency and production efficiency.

④ Fine temperature control. The temperature control can achieve an accuracy of ± 1 ° C or even ± 0.5 ° C, which is of great significance for the rotational molding of raw materials with a small processing temperature range.

⑤ Good sealing and insulation. When the rolling molding machine is running, there is no heating on the outdoor surface, and there are no gaps for direct blowing of hot air, resulting in less energy waste.

⑥ The sound is light and there is no noise. There is no significant noise or noise during the operation of the equipment, indicating that the machine is running smoothly and the gears are tightly matched.

⑦ High comprehensive energy efficiency. Various types of motors, combustion engines, etc. have low energy consumption and relatively high energy efficiency when producing the same product.

⑧ The software is configured properly. The process operation software interface of the rolling molding machine is clear, the content is comprehensive and refined, the operation is easy, the control ability is strong, and the safety factor is high.

In short, in order to do a good job, one must first sharpen their tools. A good rotational molding machine is not only a powerful equipment support for rotational molding production, but also a guarantee for high-quality products.

Phone:

Phone: Add:

Add: