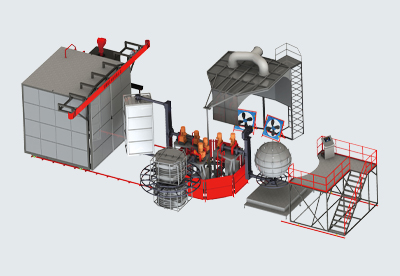

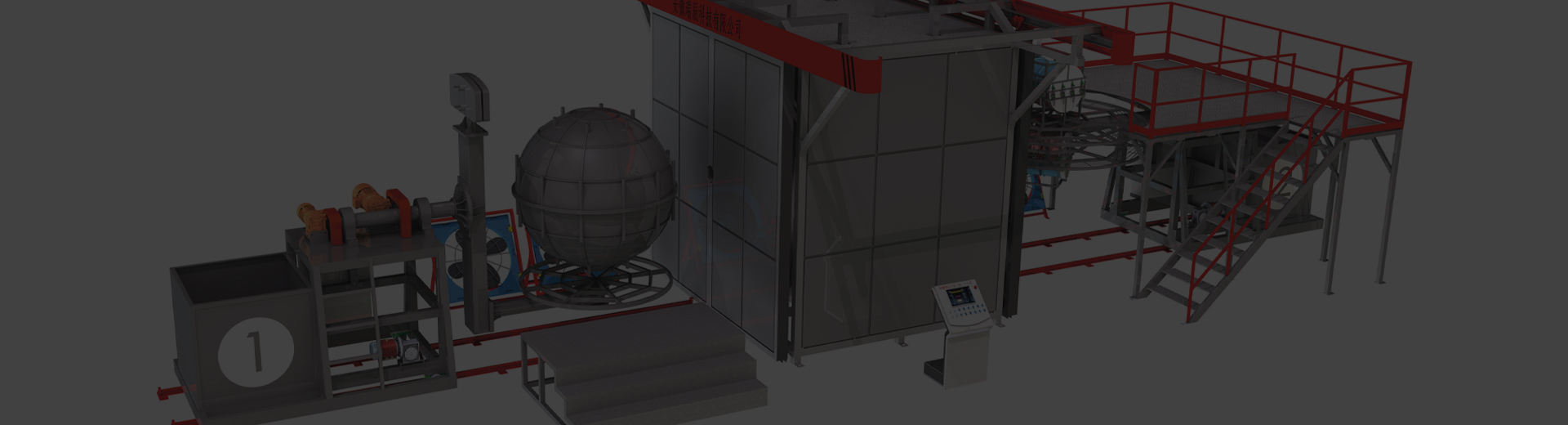

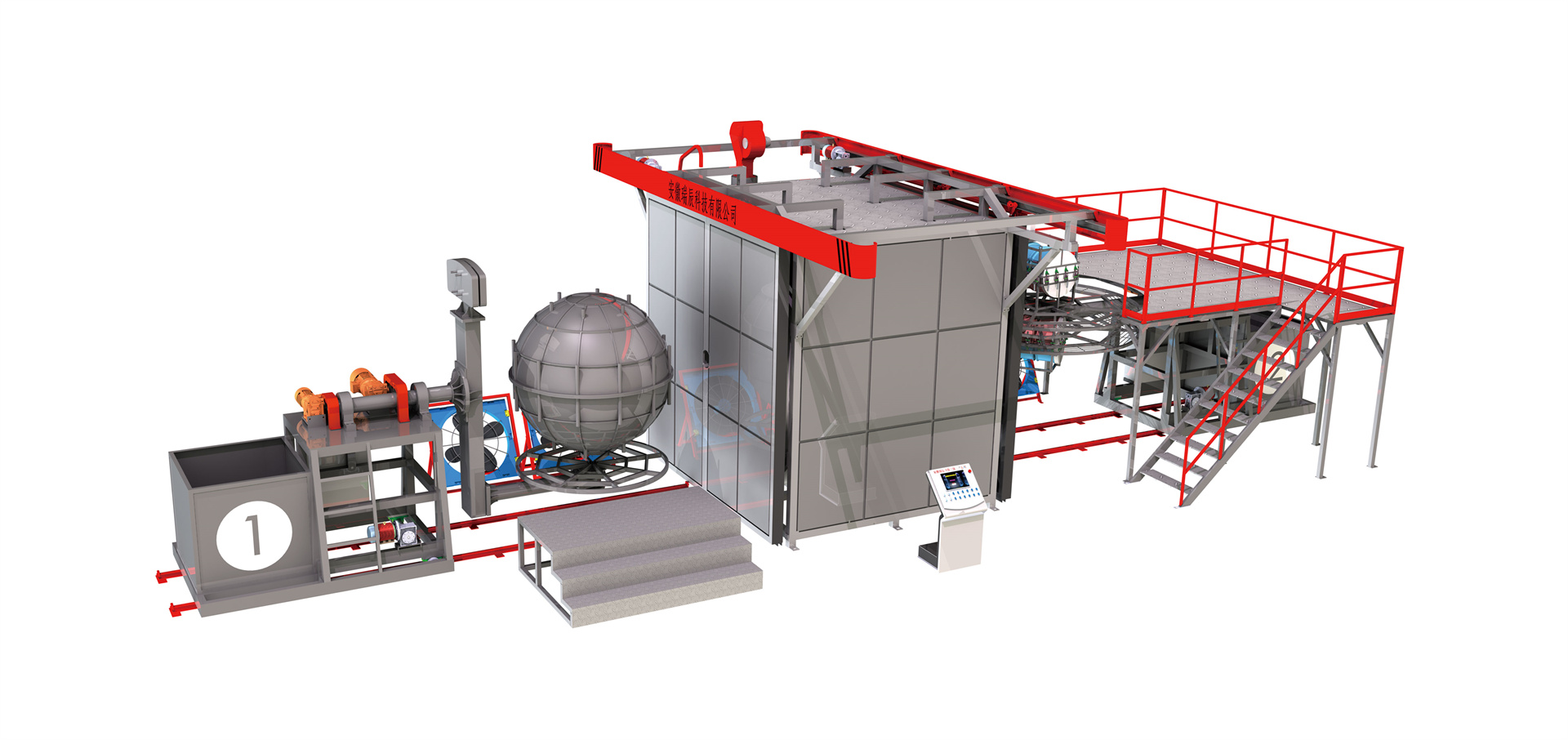

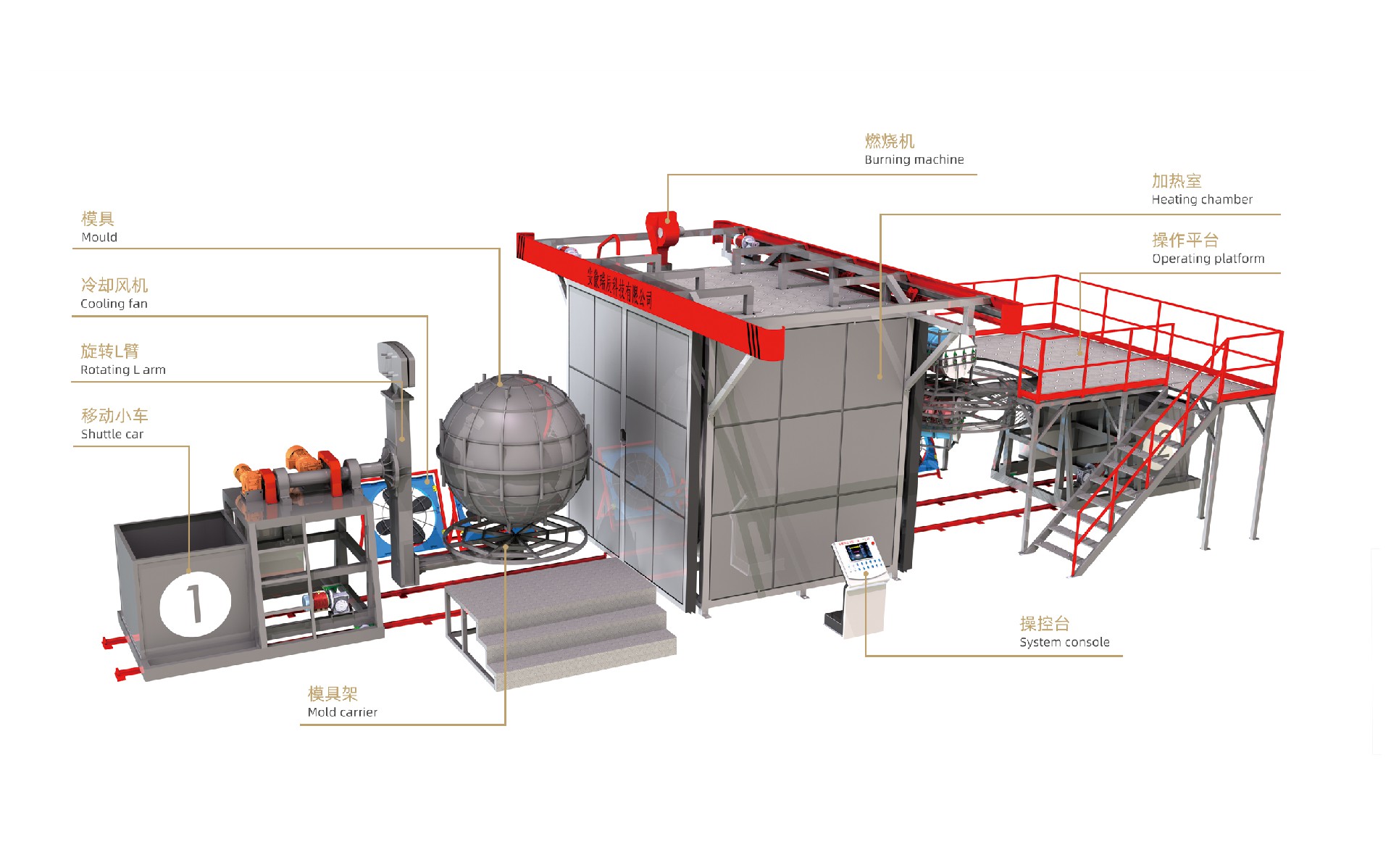

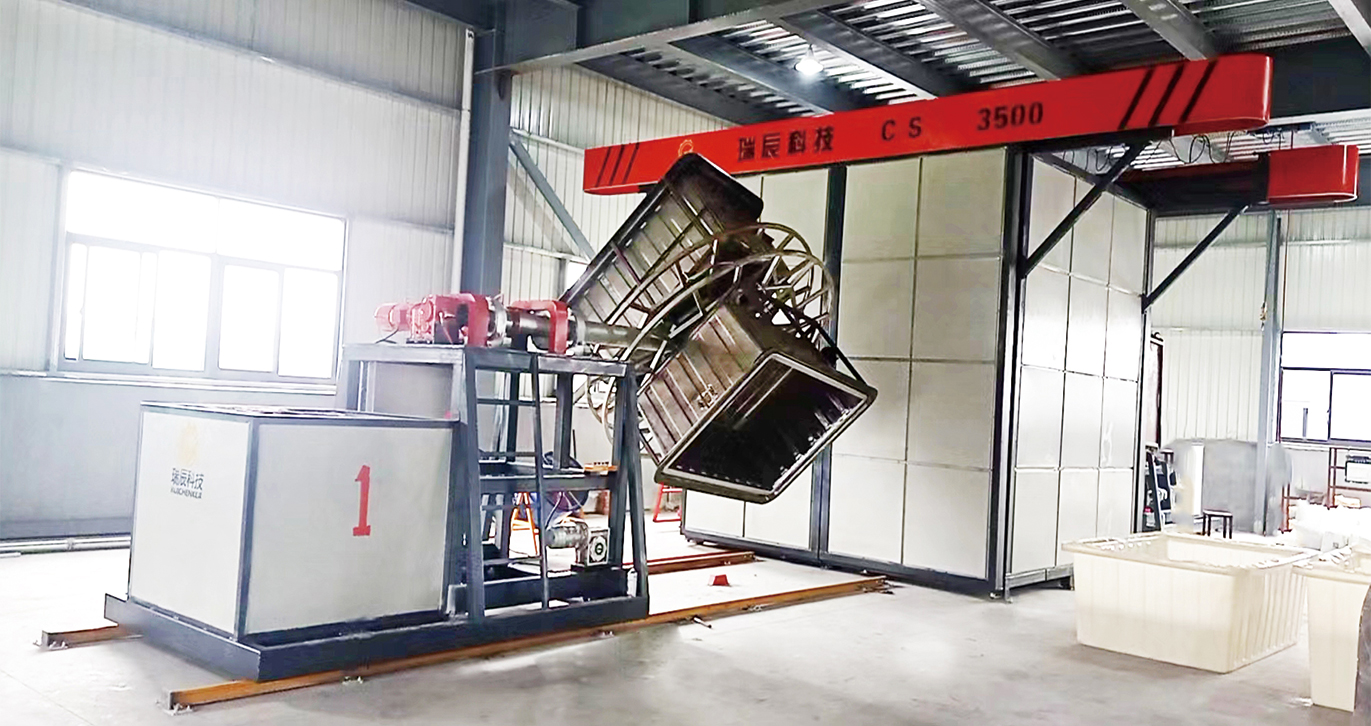

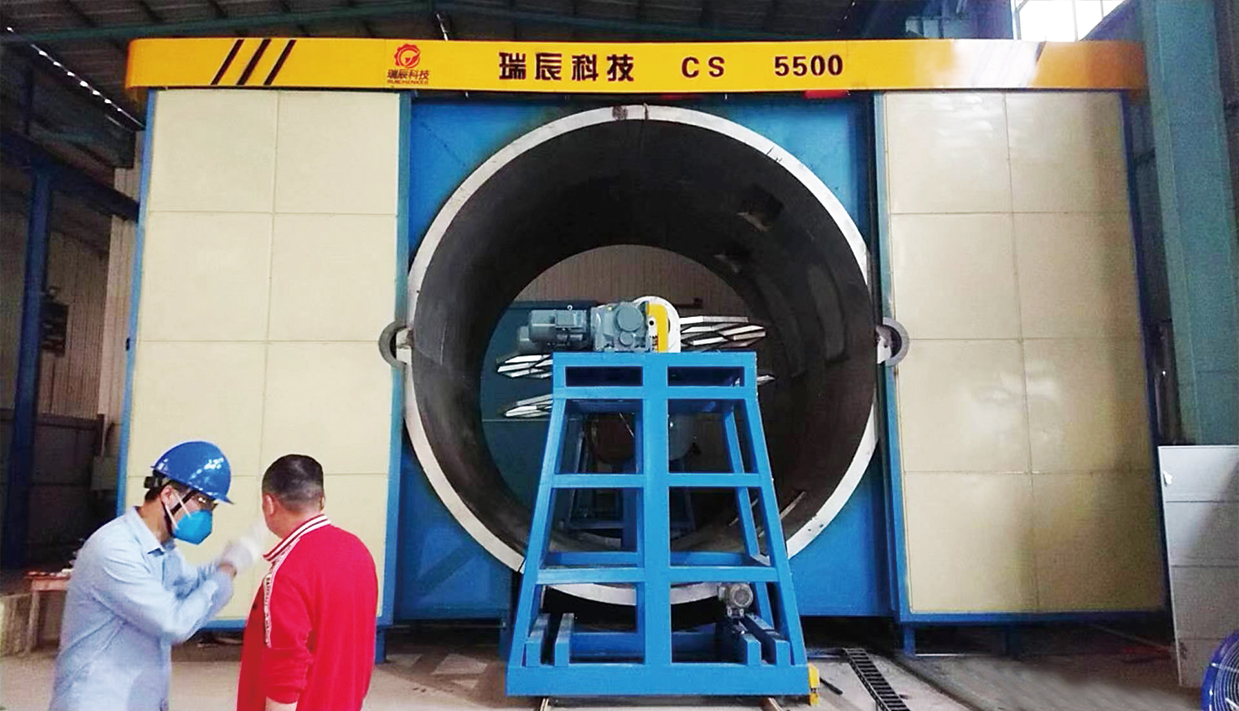

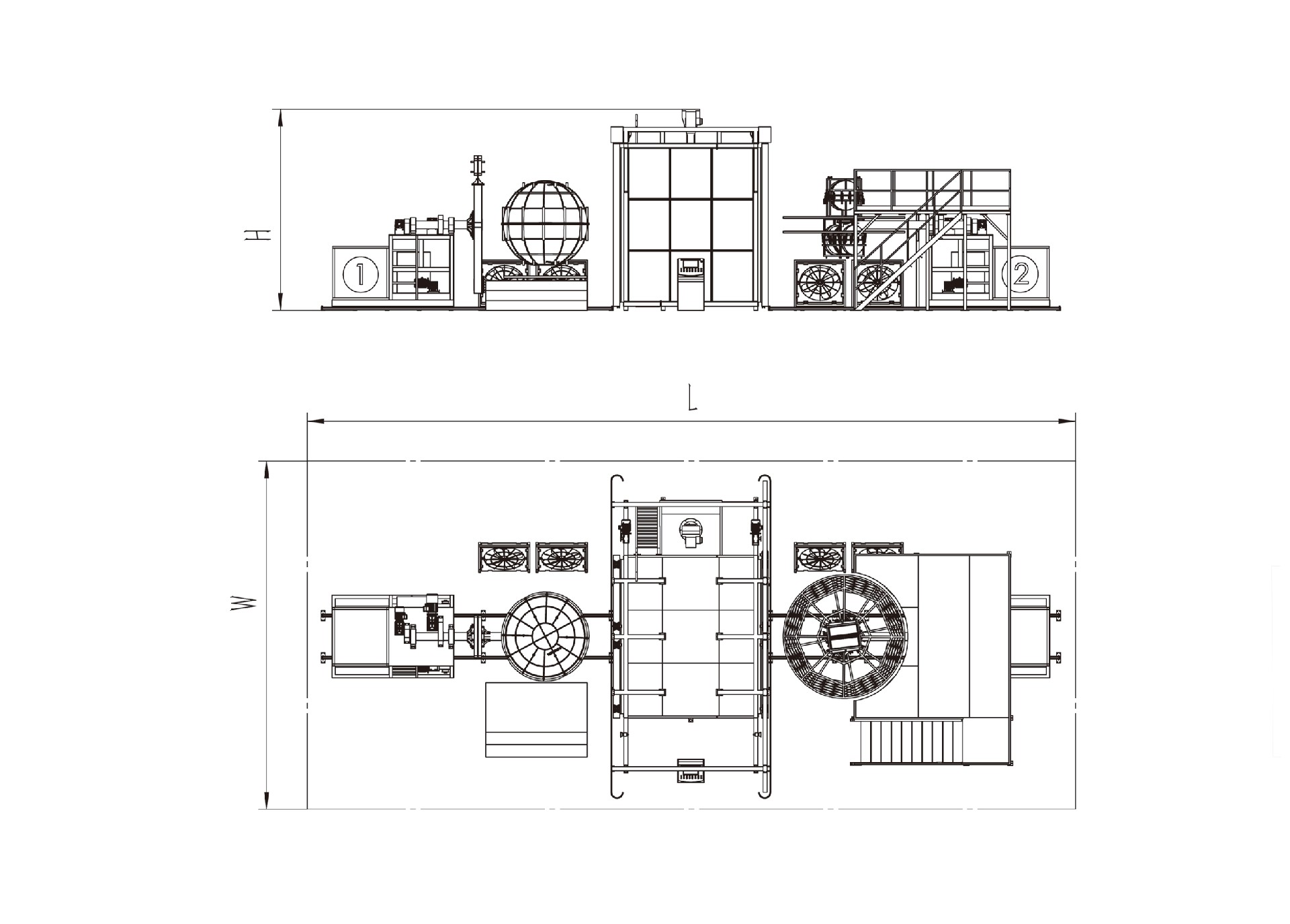

The shuttle type rotational molding machine is an economical unit, with a

fixed heating chamber and two mobile carts shuttling back and forth, which has

the advantages of small footprint and affordable price; The heating system is an

Italian Yalu combustion engine, equipped with a thermal circulation system. The

thermal circulation fan adopts high-temperature resistant stainless steel

blades, which improves the service life; Using the principle of hot air moving

upwards, the heat source directly bakes the mold, reducing energy consumption

and improving efficiency.

Suitable for producing various plastic hollow products, such as septic tanks,

military containers, rainwater wells, fuel tanks, garbage cans, dosing boxes,

anti-collision piers, floating bodies, etc.

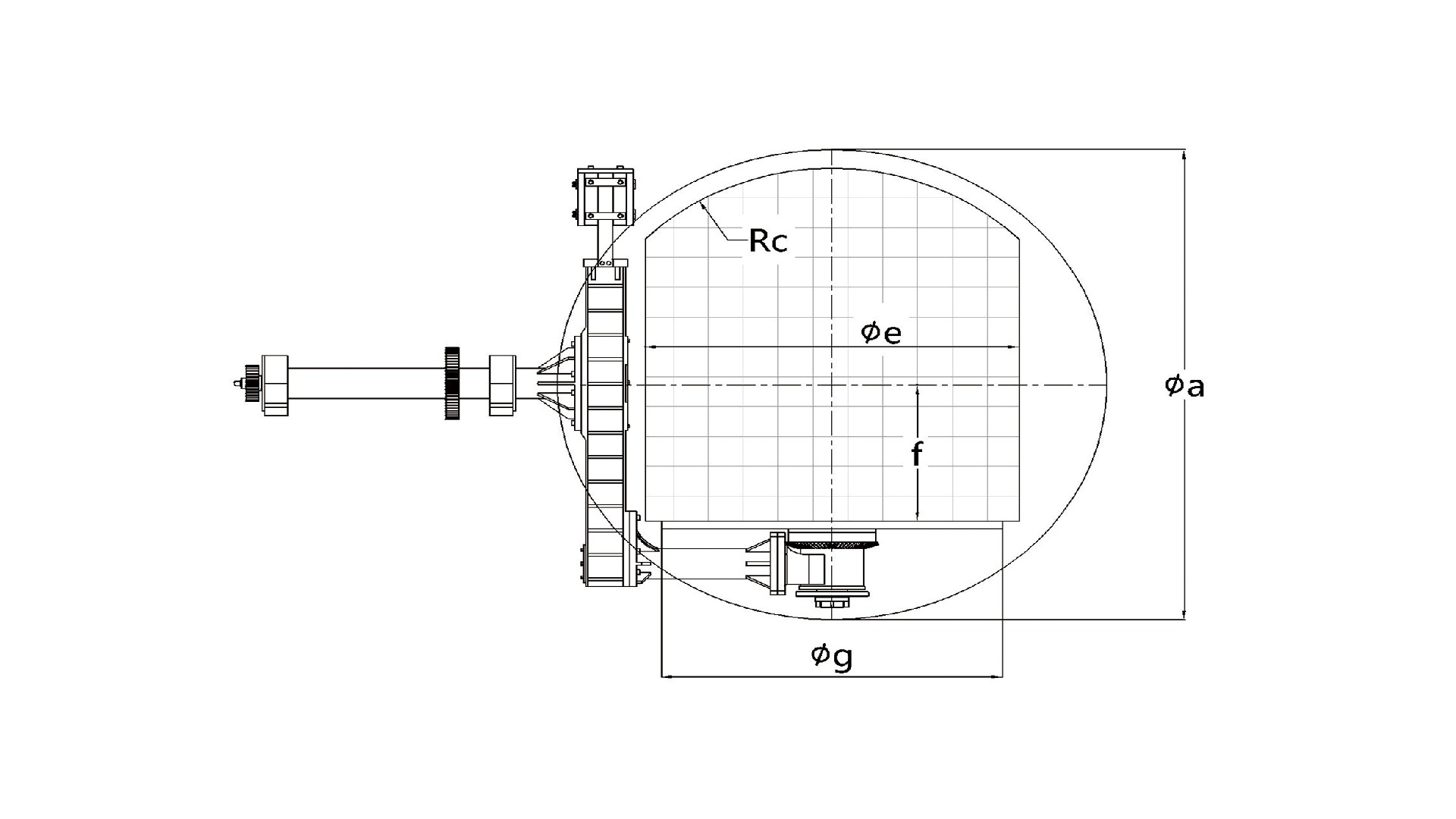

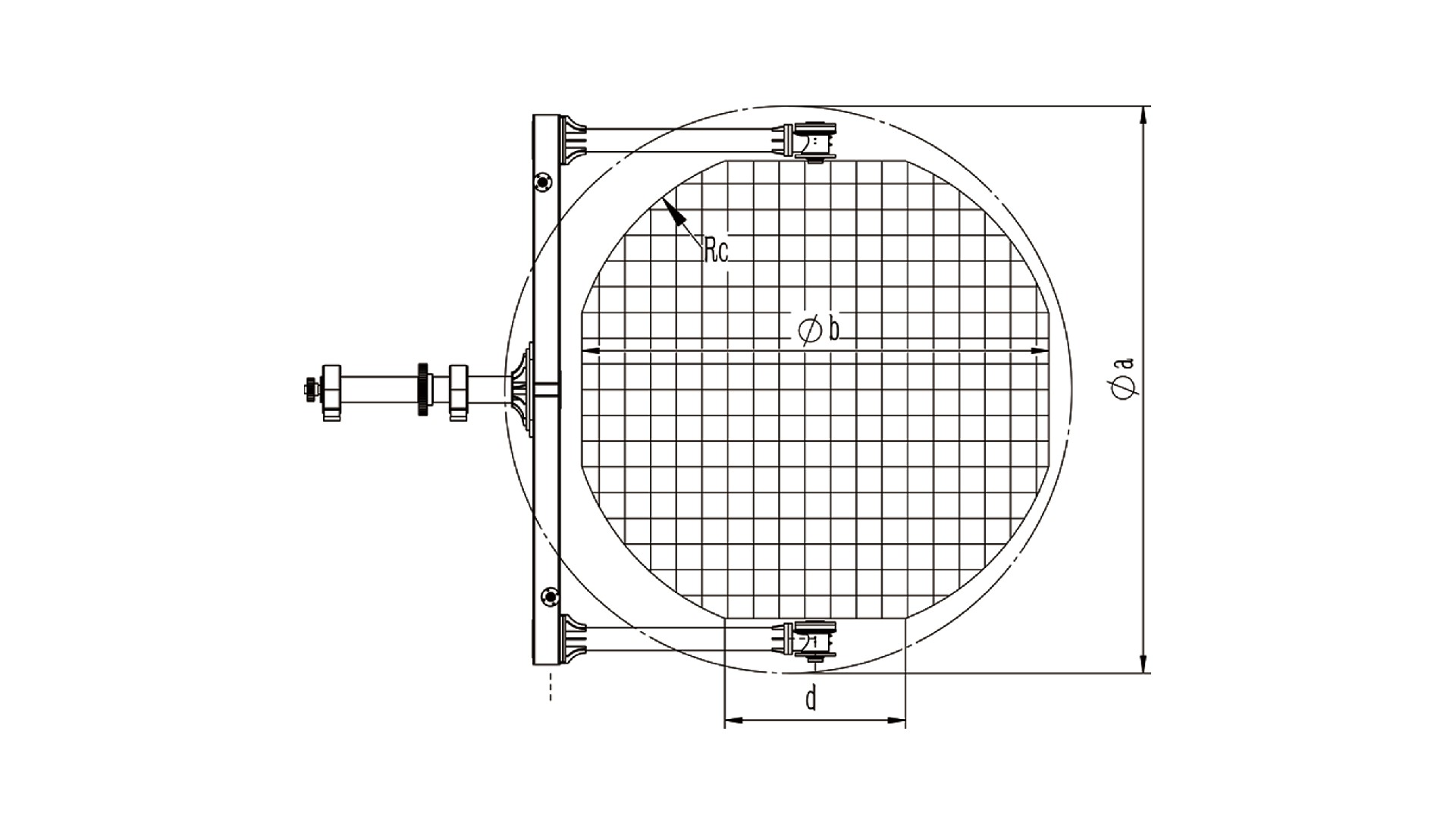

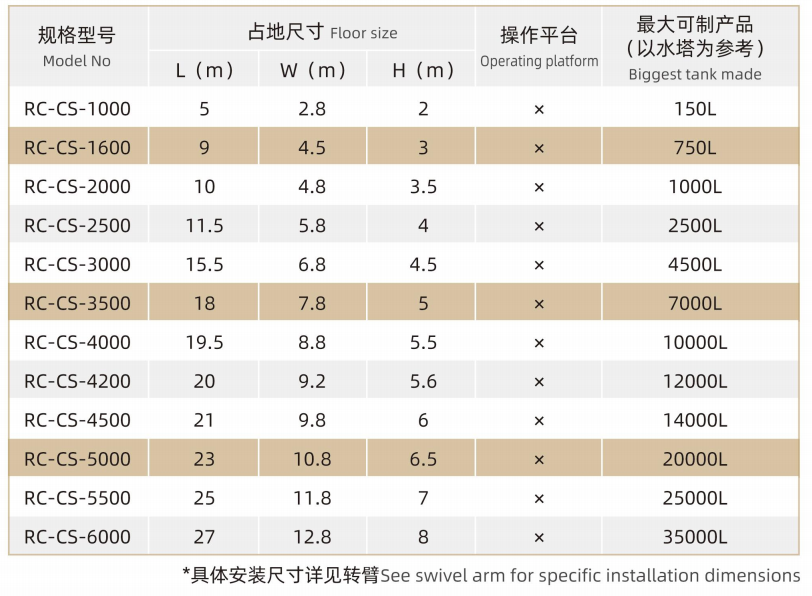

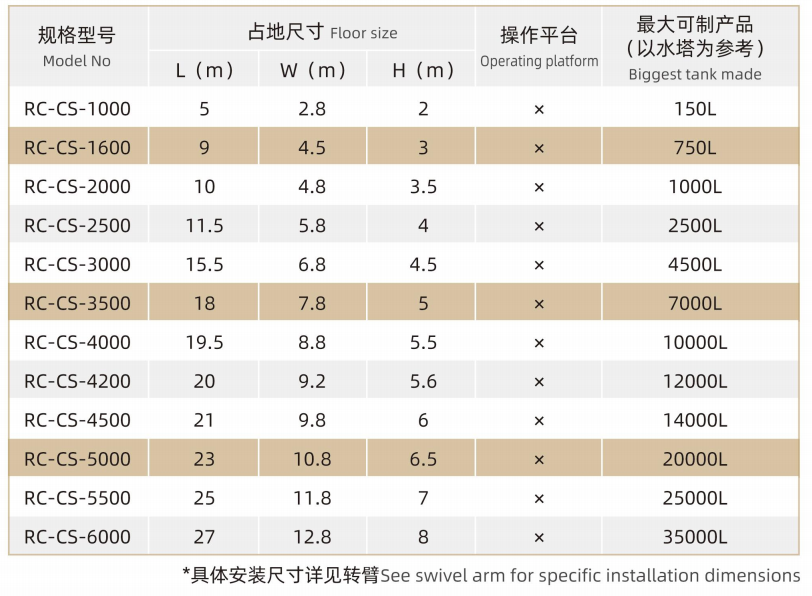

Model:RC-CS-1600、RC-CS-2000、RC-CS-2500、RC-CS-3000、RC-CS-3500、RC-CS-4000、CUSTOMIZED

Equipment features:

Having truly meaningful wireless communication technology reduces the failure

rate of broken wires to zero;

Real time monitoring of heating chamber temperature ensures product

quality;

Humanized touch interface, easy to operate;

Process flow storage function, convenient for future production

management;

Remote fault diagnosis and implementation of mobile cloud monitoring

screen;

Adopting the principle of hot air moving upwards, the heat source directly

bakes the mold, reducing energy consumption and improving efficiency;

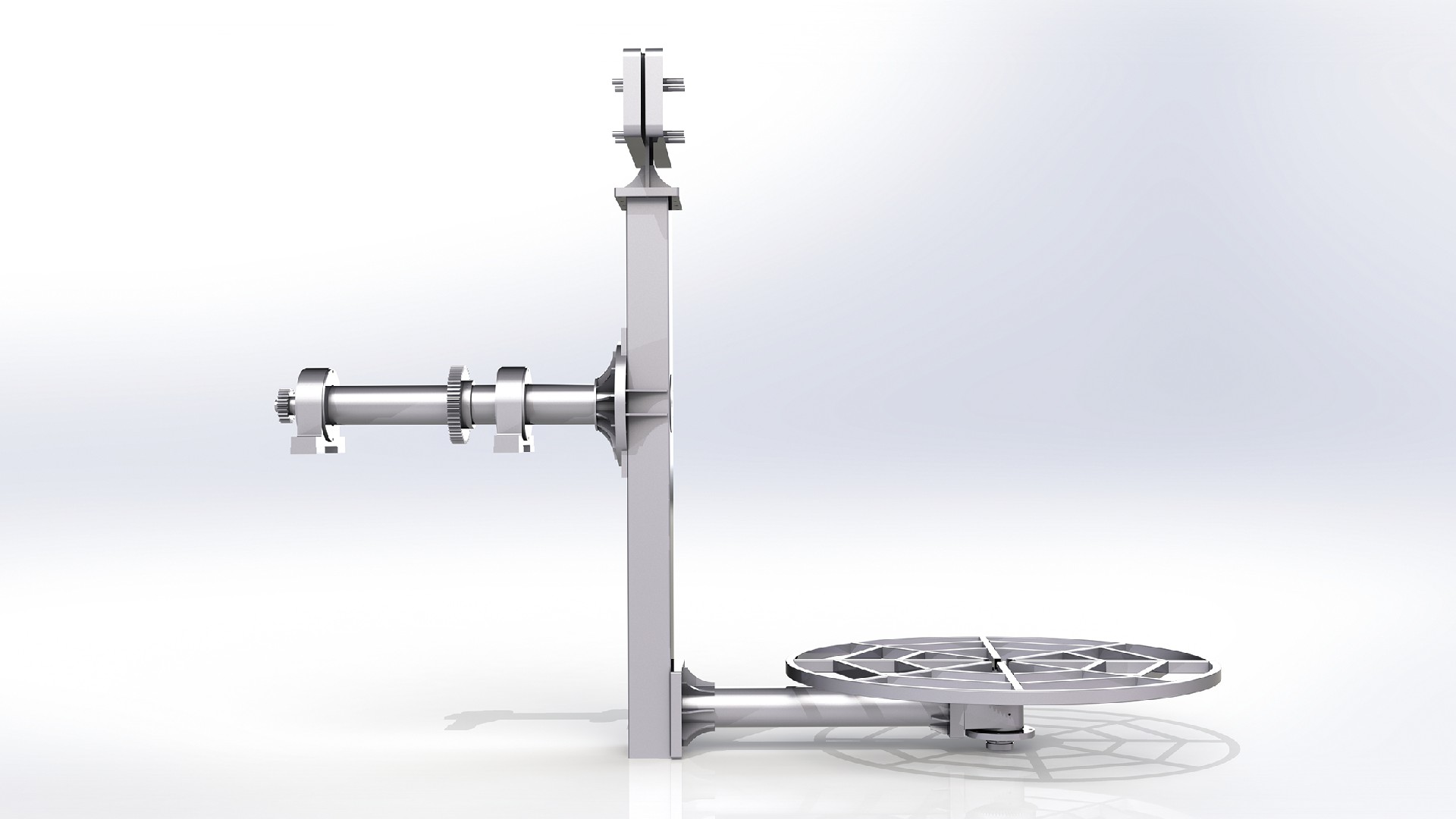

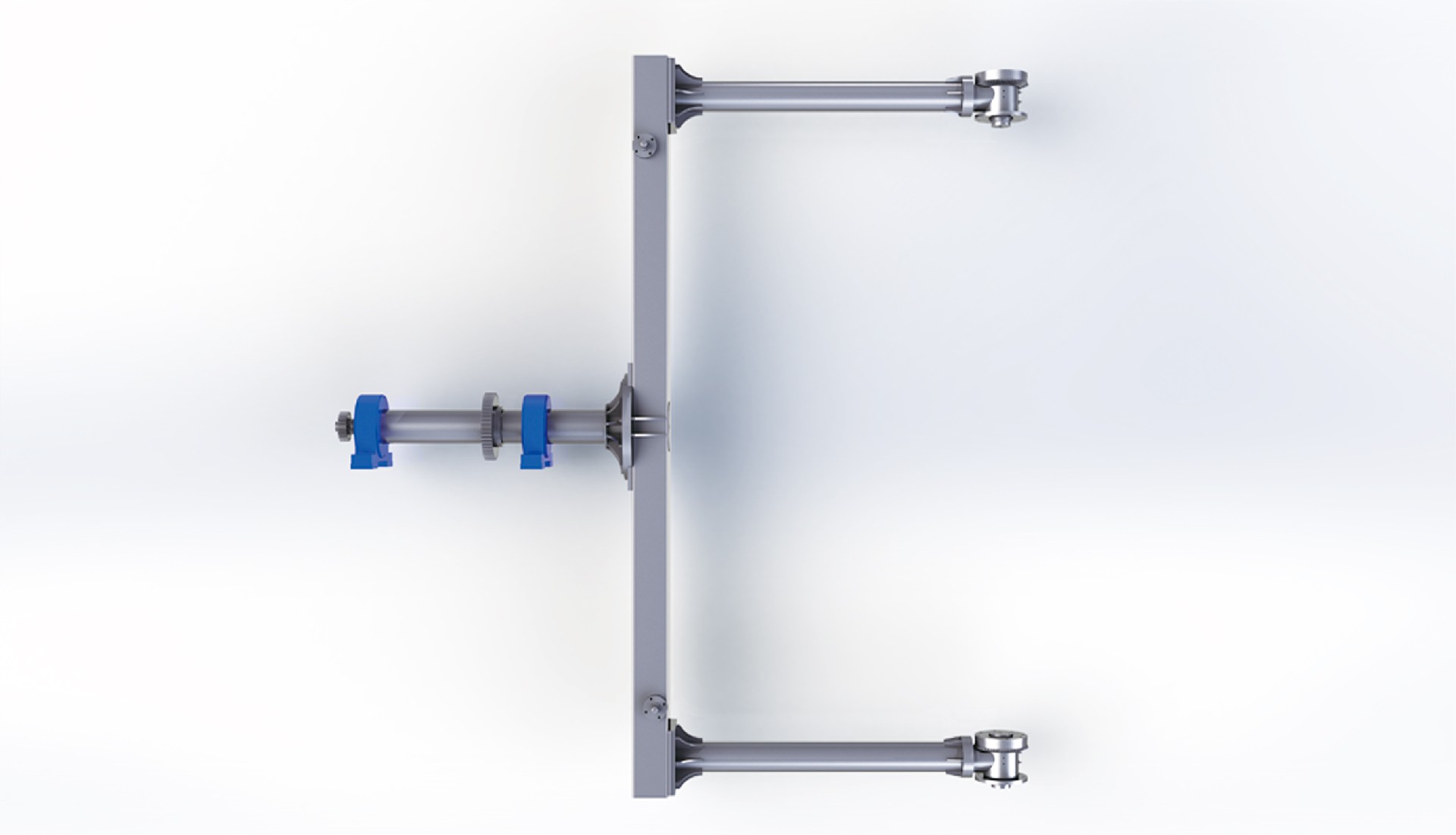

Straight arm, L-arm, and U-shaped arm are available for selection;

Available heat sources: liquefied gas, natural gas, etc.

Phone:

+8613865558212

Phone:

+8613865558212

Phone:

+8618156567276

Phone:

+8618156567276

Phone:

+8618155517338

Phone:

+8618155517338

Add:

Building A22, Aux Intelligent Manufacturing Industrial Park, Ma'anshan, Anhui Province

Add:

Building A22, Aux Intelligent Manufacturing Industrial Park, Ma'anshan, Anhui Province