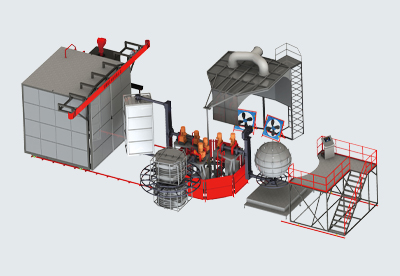

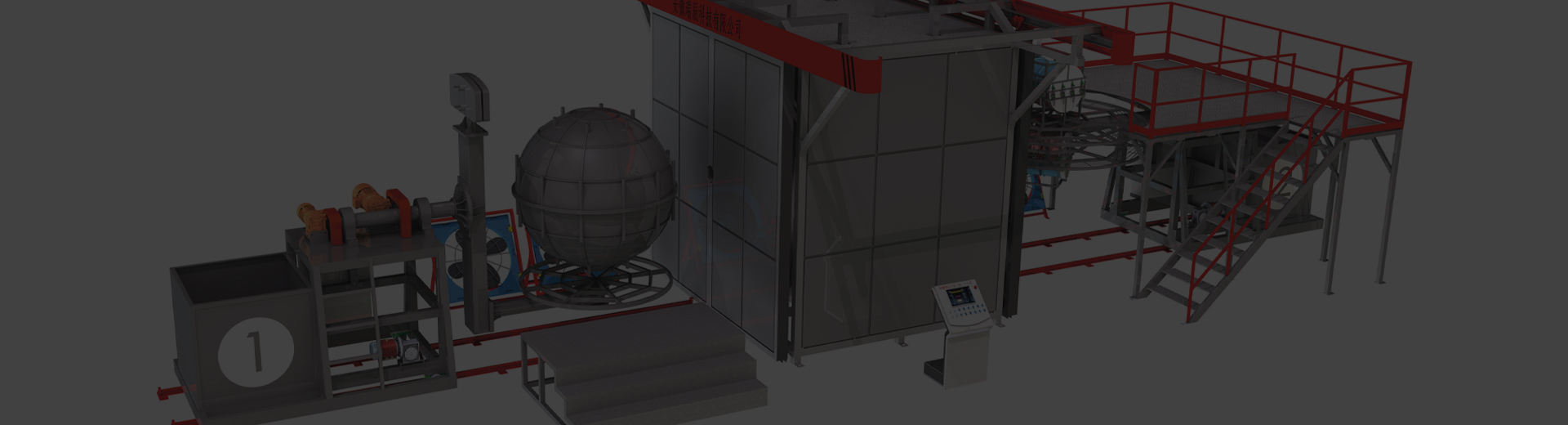

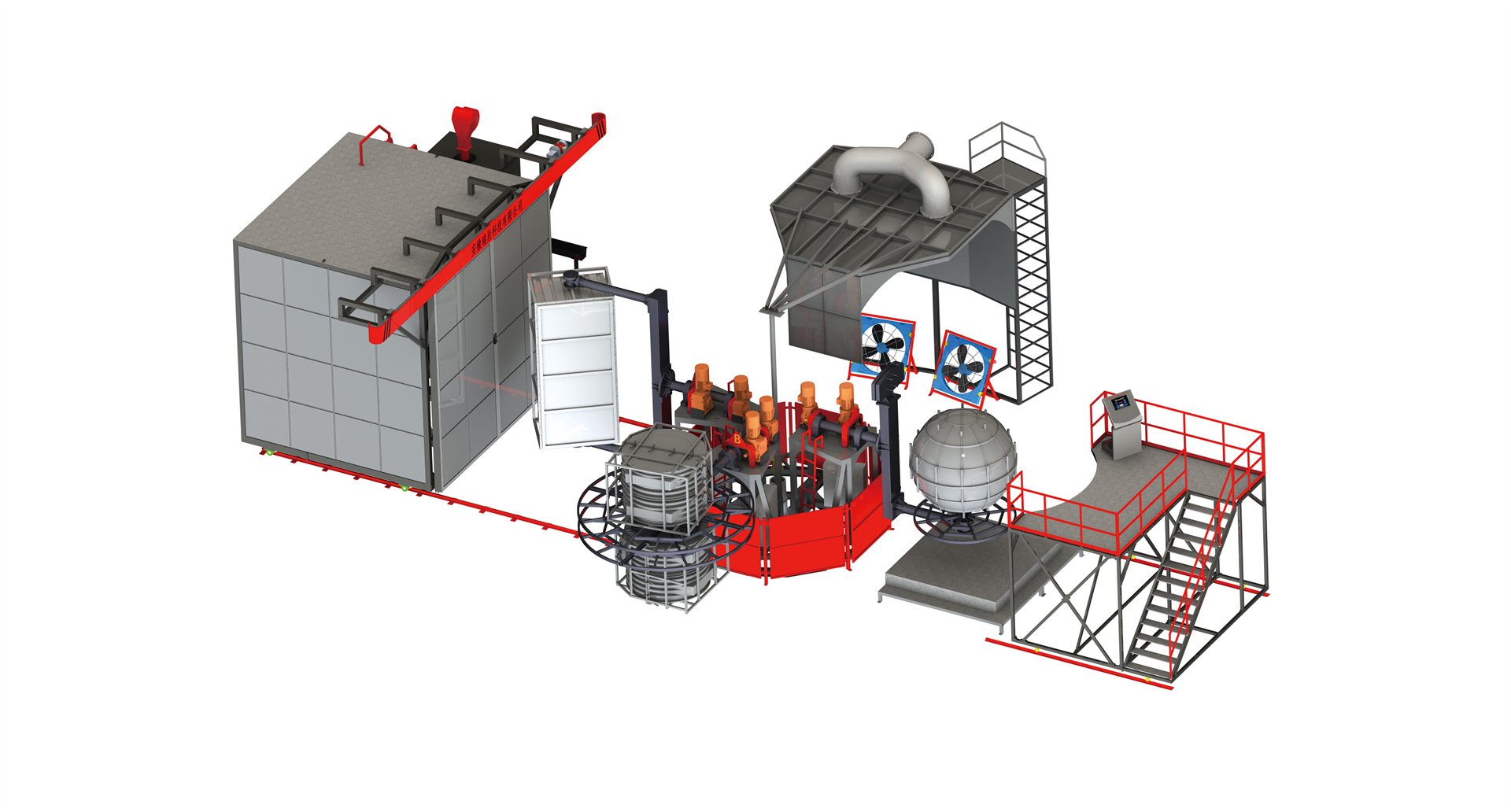

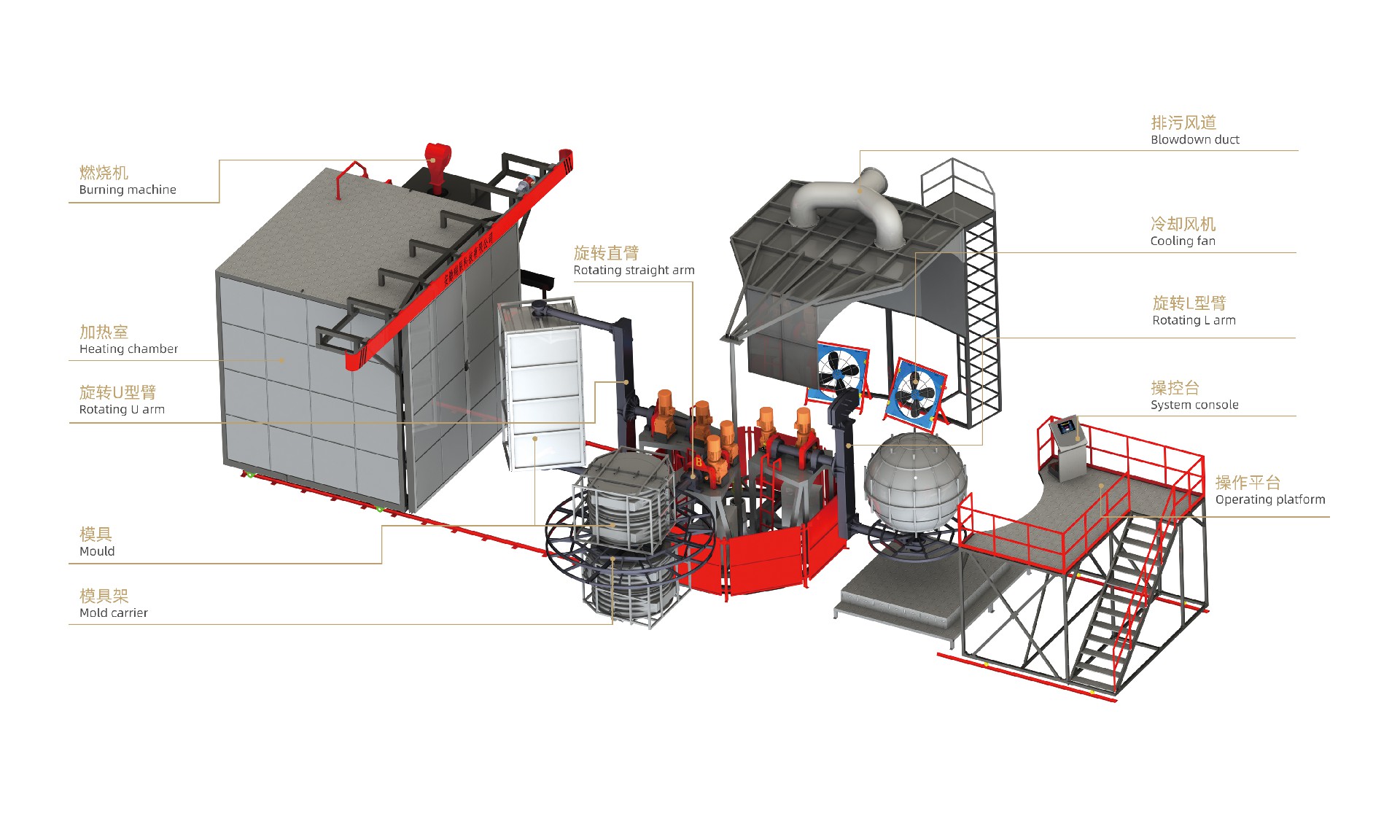

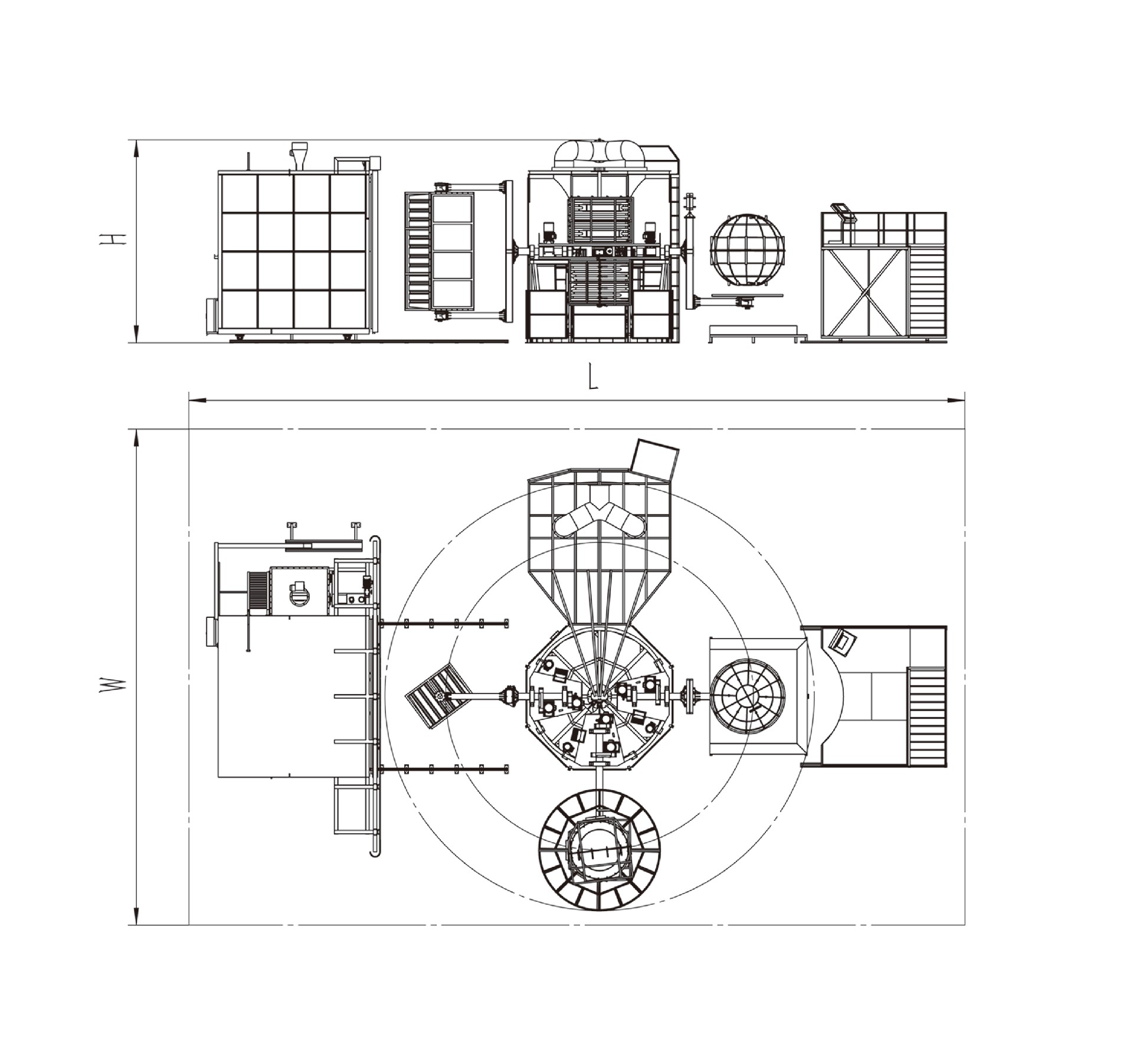

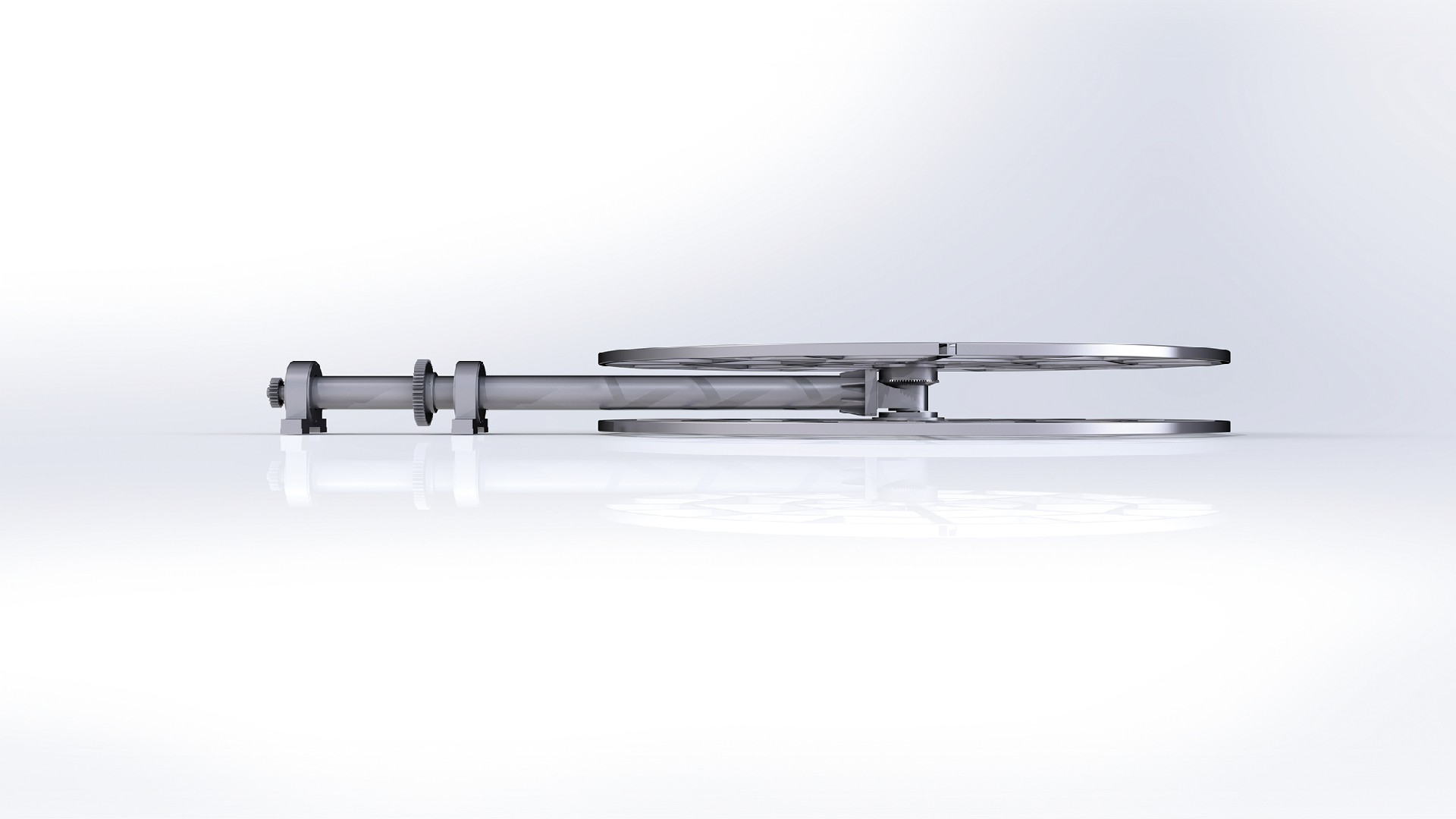

The tower rotating three arm four station rotational molding machine is a

device that uses the principle of thermoplastic rotational molding to perform

rotational molding of hollow plastic products. It consists of a rotating center

tower, a rotating arm, an automatic control system, a moving heating chamber,

and a cooling chamber.

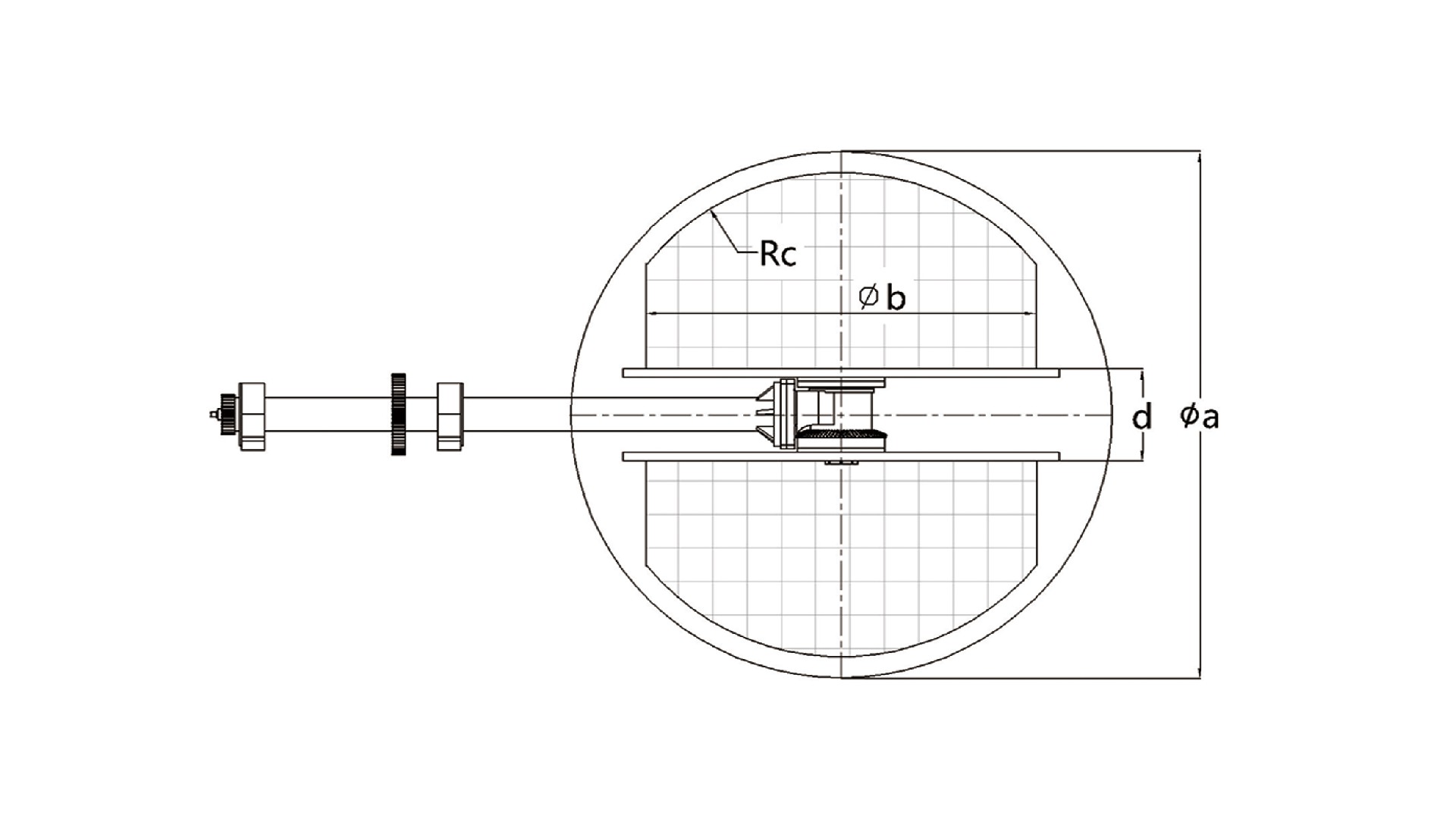

There are 3 working swivel arms, each with 4 working positions, and the

swivel arms are at a 90 degree angle to each other. Each set of swivel arms and

trolley can be operated separately without affecting the work of other swivel

arms.

The oven door rotation system adopts advantages such as motor rotation,

variable frequency speed regulation, simple structure, and easy maintenance.

This equipment uses Siemens control system and is equipped with a centralized

control cabinet, human-machine console, touch screen. The communication method

adopts true wireless communication, which ensures stable signal transmission and

low failure rate. Advantages of use: high production efficiency, small

footprint, etc.

Suitable for producing various roll molded products in large quantities, such

as military containers, septic tanks, floor scrubbers, car fuel tanks, fan

housings, luminous flower pots, inspection wells, water tanks, etc.

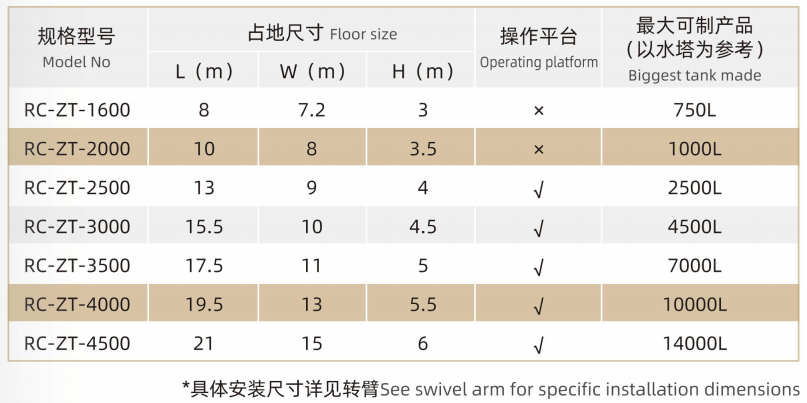

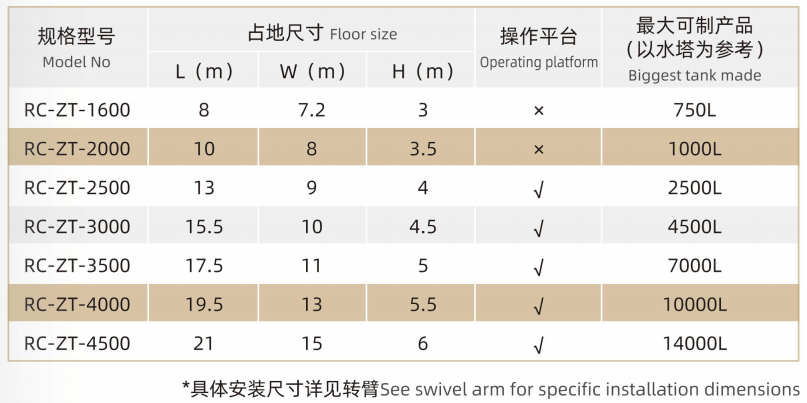

Model:RC-ZT-1600、RC-ZT-3500、RC-ZT-2000、RC-ZT-4000、RC-ZT-2500、RC-ZT-4500、RC-ZT-3000、CUSTOMIZED

Equipment features:

Having truly meaningful wireless communication technology reduces the failure

rate of broken wires to zero;

Real time monitoring of heating chamber temperature ensures product

quality;

Humanized touch interface, easy to operate;

Process flow storage function, convenient for future production

management;

Remote fault diagnosis and implementation of mobile cloud monitoring

screen;

Adopting the principle of hot air moving upwards, the heat source directly

bakes the mold, reducing energy consumption and improving efficiency;

Straight arm, L-arm, and U-shaped arm are available for selection;

Available heat sources: liquefied gas, natural gas, etc.

Phone:

+8613865558212

Phone:

+8613865558212

Phone:

+8618156567276

Phone:

+8618156567276

Phone:

+8618155517338

Phone:

+8618155517338

Add:

Building A22, Aux Intelligent Manufacturing Industrial Park, Ma'anshan, Anhui Province

Add:

Building A22, Aux Intelligent Manufacturing Industrial Park, Ma'anshan, Anhui Province