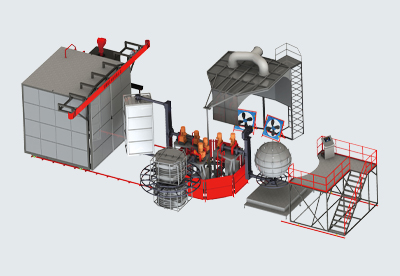

Although rotational molding has made great progress, there are still many shortcomings compared to injection molding and extrusion molding, and there are still many areas that need to be improved in rotational molding. The development prospects of rotational molding equipment are mainly concentrated in the following aspects:

1. Contemporary production, processing and forming technology

In addition to the trend towards production and manufacturing automation technology, rotational molding processing technology also has new development trends in mold and heating methods, such as the technical aspect of membrane pressurization (i.e. inflating the structure with air during a certain period of heating and cooling); Technical aspects of membrane cooling (reducing heating and cooling time, and minimizing production and processing cycle time); Technological improvements such as infrared microwave heating enhance the efficiency and quality of forming production and processing.

2. New epoxy resin for rotational molding

The wide range of raw materials for product research and development is of crucial practical significance for the development of rotational molding products. In addition to polyethylene resin, the research and development of rotational molding specific raw materials such as polypropylene, polyethylene, polypropylene cool, polyester, ASS, SAN, and polyurethane elastomers is necessary to consider the production, processing, and shaping of products.

3. Improve the automation technology and precision level of rotational molding equipment

The automation technology level of contemporary rotational molding equipment still differs greatly from injection molding processes. If the automation technology level of machine equipment can be improved to reduce the production and processing cycle time of rotational molding products, then its competitiveness with other production and processing methods will be further enhanced.

4. Design scheme and decoration design of the product

The trend is to use rotational molding processing technology to produce products with extraordinary artistic creativity, and the surface and design patterns are beneficial for improving the competitiveness of rotational molding products.

Rotational molding technology has strong vitality and is a processing technology that is worth paying attention to in terms of aspect ratio. We attach great importance to solving rotational molding processing technology and use it to produce various cost-effective plastic products. Especially in comparison with capitalist countries, there is still a significant difference in the technical aspects of rotational molding in China. We should actively digest and absorb superior overseas technologies, increase scientific research on processing techniques, rotational molding equipment, and molds, accelerate the development of national standards for rotational molding, and continue to produce high-quality rotational molding products for the sales market.

Phone:

Phone: Add:

Add: