Phone:

+8613865558212

Phone:

+8613865558212

Phone:

+8618156567276

Phone:

+8618156567276

Phone:

+8618155517338

Phone:

+8618155517338

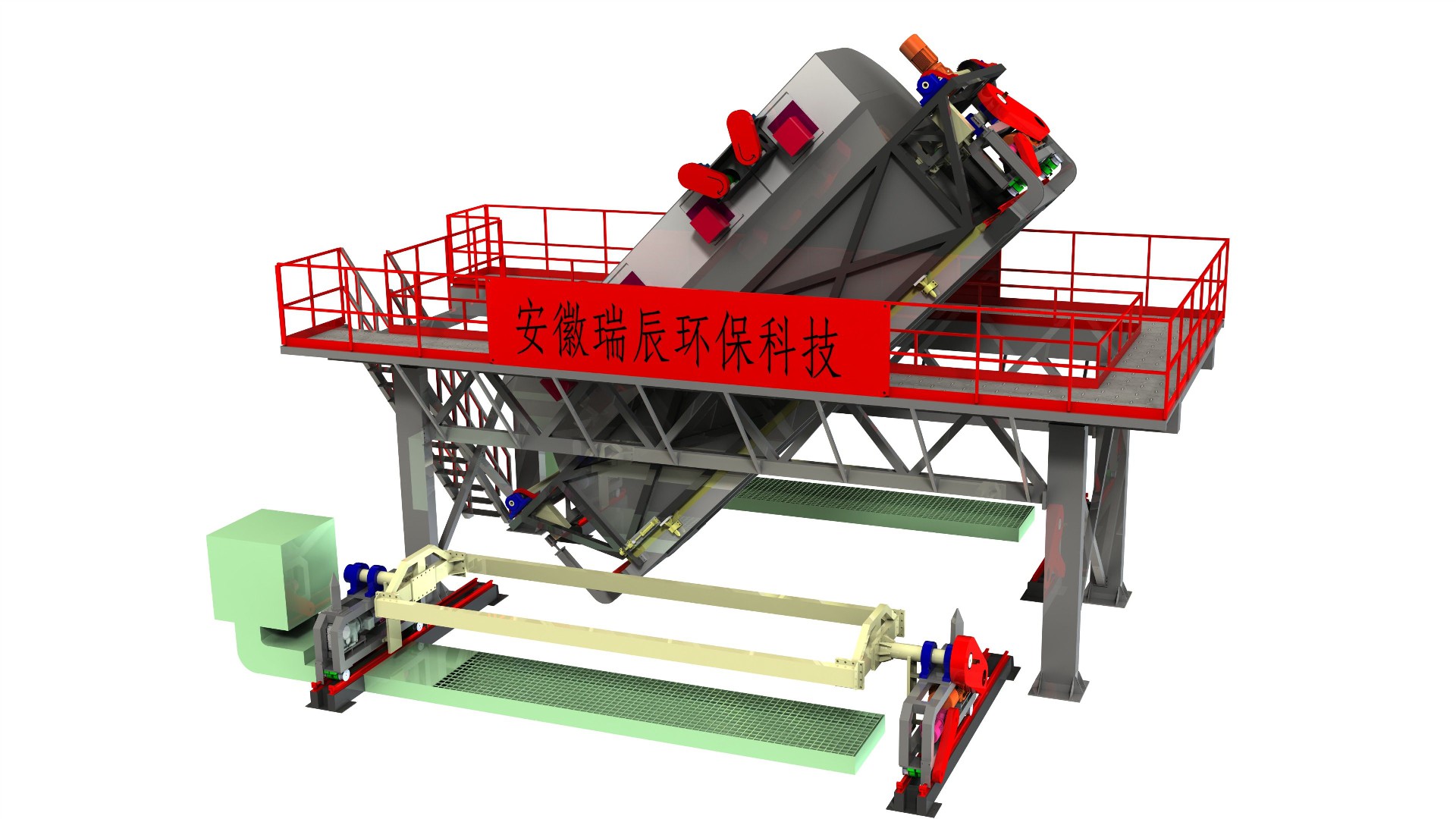

Add:

Building A22, Aux Intelligent Manufacturing Industrial Park, Ma'anshan, Anhui Province

Add:

Building A22, Aux Intelligent Manufacturing Industrial Park, Ma'anshan, Anhui Province